As architects, we are challenged to solve complex design problems that must take in to account a myriad of factors, including building codes, material selection, security and safety concerns. When tasked with designing for early childhood centers, these challenges are taken to a whole new level. We must carefully balance the various levels of need each child’s age presents with the needs of the caregivers, all while providing an environment that encourages learning, growth, and safety. As more and more companies are seeing the value in on-site child care facilities, architects will be faced with integrating these centers into workplace projects.

Mackey Mitchell recently completed documents for a renovation to the Monsanto – Child Development Center (CDC), operated by Bright Horizons. The CDC was constructed over twenty years ago and was ready for a facelift. The original project scope included new finishes, casework, lighting, and ADA (Americans with Disabilities Act) improvements. What began as a simple refresh for an out-dated facility would quickly morph into a highly coordinated, research-filled journey, that would ultimately lead to a safe, creative solution for the owner and occupants.

As with any large corporate campus, employee and visitor safety are critical priorities at Monsanto. We took this into account when asking caregivers to show us challenges they faced performing their daily responsibilities. One example in particular really stood out – the use of a freestanding step stool to assist toddlers onto a diaper changing station. While showing us her routine, the caregiver commented that a place to store the step stool or pull-out steps that could be stored when not in use would be an acceptable solution.

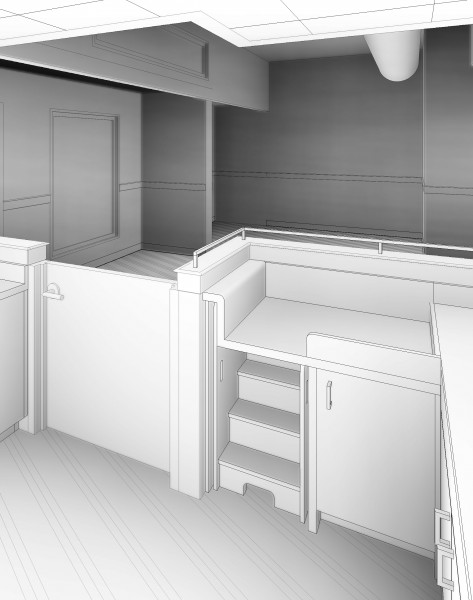

After our visit, schematic concepts to solve the problem were developed. Monsanto’s safety committee initially raised many safety flags over the pull-out steps solution, and it was decided to forego this change. Weeks later, when the safety committee went to the CDC to observe daily routines and operations, they witnessed firsthand how much of a challenge the caregivers faced assisting toddlers onto the changing table. This observation catapulted the pull-out steps idea back into the project, but we needed to find a way to make the steps and their sliding operation safer.

The design team initially explored pre-manufactured changing stations that already included the pull-out steps. However, with the existing layout and tight space constraints, the team realized that a custom solution was the only way to properly address the function needs and safety concerns.

After discussion, it was determined that front approach steps were preferred over side approach. At the next safety committee meeting, we were able to gain critical insight into their safety concerns, the most important being the ability to prevent falling or slipping off the stairs, as well as the durability of the hardware. Anyone that is familiar with childcare routines knows how many times a day those stairs would be used! Due to the custom nature of the steps, the design team also referenced and conformed to ASTM (American Society for Testing and Materials) standards for the product design of baby changing tables and baby cribs.

The winning design solution was to raise one side of the steps to act as a guardrail, while the opposite side would remain open to allow caregivers to assist the child. Abrasive, slip resistant strips were added to each step, and industrial drawer guides capable of holding up to 400 lbs were specified. The design was further enhanced by adding hand holes to assist in pulling steps out along with furniture glides to help protect the floor and create even more stability.

The project is still under construction as of April 2016. Once completed, we will update with images of the completed center.

By: Matthew Roeder

By: Matthew Roeder